Planned Production Process With In-Line QC Checks

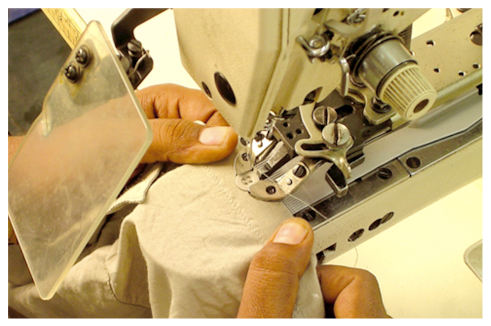

Investment in in-house infrastructure paves the way for a steady present and an even stronger future. The manufacturing facilities of FFIPL are equipped with the latest machines required for garment production as per the international standards.

Add to it a large pool of skilled and semi-skilled workforce managed by expert garment professionals and you have a company you can rely on to source garments from India. Up-gradation of machinery is an ongoing process at FFIPL. It has also resulted in the reduction of production lead time for the benefit of its buyers.

Planned approach to production, in-line quality checks, strict adherence to customer specifications and use of high quality fabrics, trimmings and accessories are some of the factors that make FFIPL’s garments a notch better than others.

The other stages of production also have sophisticated machines like Perk Dry Cleaning Machine and other washing machines, Sand Blasting Machines, etc. The objective is to ensure super quality, optimum production and timely execution of orders.

One look at the garment manufactured at FFIPL’s manufacturing facility and you will not find it wanting in quality of workmanship, trimmings or quality of fabric.

Integrated In-house Infrastructure Means Assurance Of Quality

FFIPL believes that a quality manufacturing facility run by qualified personnel produces quality garments. Its manufacturing facilities have been audited by several reputed and large buyers over the years. While processing a typical order, the production team of FFIPL de-constructs the buyer's sample and carefully notes the specifications. Then fabric, trimmings and accessories are sourced from known and tested vendors. A trial run removes all glitches and the garment is perfected as per the requirements for production. In-line production checks and random checks by the management ensure that you get zero defect and child safe garments.

Every garment being produced undergoes several stringent QC checks at each stage of production by the QC team. Moreover, the work culture of the company is very quality centric and therefore leaves little or no room for errors Hand and Computerised embroidery on delicate fabrics like viscose, lycra, silk, polyester, cotton, tissue, net, etc is one of the specialities of FFIPL. It has also developed special skills in denim over-dyeing, tinting and dirty wash. Sand blasting is yet another strength.

The age old art of fine and intricate hand embroidery has been flourishing in the hands of master craftsmen at FFIPL.

Other skills include tie and die process, garments combining knitted and woven fabrics, laser engraving on any fabric or garment and pigment dyeing.

The designers of FFIPL constantly experiment with fabrics, colour combinations and trimmings etc to create new garments and designs. They strive hard to keep pace with ever changing trends in international fashion. The idea is to give our customers more than value for their money..